About

Miami Wiipica, LLC is a SBA certified Tribally owned 8(a) company, one of the family of companies owned by the Miami Tribe of Oklahoma and reporting to the Tribe’s economic division, Miami Nation Enterprises. Wiipica provides construction, design/build, engineering, and operations and maintenance services nation-wide. Wiipica and its staff have deep experience in providing services and solutions to the Federal Government.

Hunter Saak is a national leader in modular structure manufacturing and installation, with strong versatility in customizing structures for specific purposes. Hunter Saak also has a nation-wide scope, with robust capabilities in delivering specialized structures on time and on budget. Hunter Saak was awarded the Modular Building Institute’s Award of Distinction in 2011 for a modular project at Camp Pendleton – NAVFAC.

Together, Wiipica and Hunter Saak have combined their strengths to provide expedited, tailored solutions for critical national needs. Wiipica Hunter Saak offers the Federal government a Made in USA product. These structures are available for lease or sale, and we provide design, installation, and utilities installation.

POINT OF CONTACT

Harry Brown

609-230-4425

hbrown@mn-e.com

Tribal 8(a) Acquisition Solutions

As a SBA certified Tribally owned 8(a), Wiipica Hunter Saak (WHS) enjoys a unique relationship with the Federal government, one that allows us to collaborate and respond to emergency needs. When deemed appropriate, WHS provides services and products as a sole source solution, which is non-protestable up to $100 M.

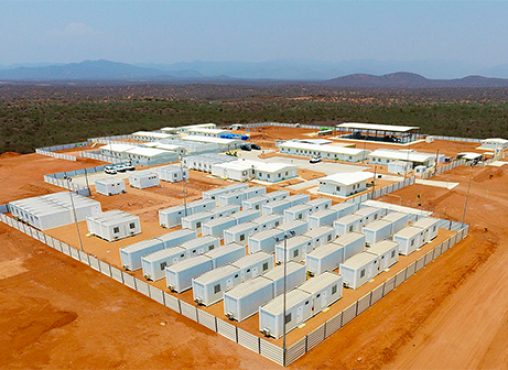

Command Box – Prefabricated Modular Structures and Construction Technology/Capabilities

- The Command Box can meet any space need. These units are typically 8×20 feet and can be customized. These units can be used for barracks, camps, site offices, classrooms, staff accommodations, hospitals, recreation rooms, logistics centers, open plan catering halls, and multistory sleeping camps.

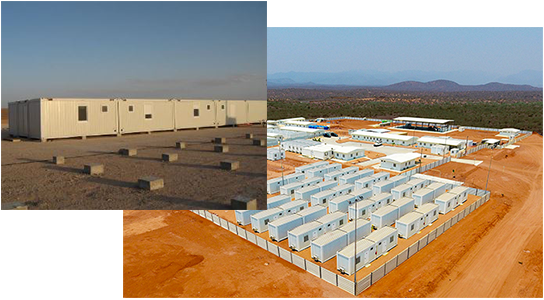

- The Command box can be stacked and coupled side by side to create complexes of any size, meeting practically any need. These units are constructed with interchangeable panels allowing for an infinite number of designs. The system can be transported completely knocked down and set up at the final destination. Transportation of the units is very cost effective and efficient. Single modules can easily be moved via forklift. The Command Box is climate controlled and supplied with an HVAC unit per module. Units are prewired with electrical wiring. They are ground mounted for easy set up and stackable to create multistory structures up to three floors high.

Performance of Joint Venture

Our scope includes design, manufacturing, and utilities installation for the lease and sale of modular buildings. Our structures can be used in both permanent and temporary applications. Our combined capabilities and operational approach produce rapid, expedited delivery of products and services.

WHS has been awarded a 9K SF campus-style modular SCIF project at Guantanamo Naval Base (GITMO). We are also the recipient of three awards to provide 21K SF multi-floor modular SCIF complexes at Tyndall AFB. Our team is currently undertaking a project awarded by the US National Park Service providing 100 modular homes at Yellowstone National Park.

Command Box – A Prefabricated Modular Structure Made in America

A Camp Lodging Solution

The Command Box is a multipurpose accommodation solution built within the dimensions of a standard 8×20 container. It has the ability to be transported knocked down to 25% of its assembled size. Once assembled the module is outfitted with an HVAC system for climate control. The modules provide a comfortable space for classrooms, office space, or sleeping. The units can be coupled and stacked to create multistory functional space. The Command Box is the fastest space solution now on the market for mobilization.

A great solution for Covid (Virus) testing and isolation units.

Design/Schedule

Units are

- Climate controlled

- Non-combustible

- Cold steel framed construction with interchangeable galvanized and insulated panelized wall system

- Reconfigurable and reusable

- Customized for use as housing (either permanent or temporary), swing space, office, operations, dining/food prep, medical (including isolation units), logistics, SCIFs, and HAZMAT storage solutions

- Certified by OSHA and NAVFAC

Shipping and Scheduling

- Estimated timeline for product development/deployment is a very reasonable 30 to 45 days for manufacture.

- Knocked down units transport at 25% of their assembled box form.

- Once onsite The Command Box can be assembled within hours.